Title: Unveiling the Wonders of Spheroidized Cast Iron Microstructure: A Metallurgist's Perspective

Introduction:

As a metallurgist, I am excited to explore the intriguing world of spheroidized cast iron microstructure. In this post, I aim to provide a comprehensive explanation of spheroidization in cast iron, its impact on microstructure, and the resulting mechanical properties. Join me on this fascinating journey into the realm of metallurgy!

1. Understanding Cast Iron Microstructure:

- Cast iron is a widely used material known for its excellent castability and unique microstructure.

- The microstructure of cast iron typically consists of graphite flakes or nodules embedded in a metallic matrix, which can significantly influence its mechanical properties.

- Various factors, such as alloy composition, cooling rate, and heat treatment, affect the microstructure of cast iron.

2. Spheroidization Process in Cast Iron:

- Spheroidization in cast iron involves transforming the flake or lamellar graphite structure into nodular or spheroidal graphite.

- The process requires controlled heat treatment to promote the formation of graphite nodules.

- Spheroidization is commonly achieved through the addition of specific alloying elements or the modification of the casting process.

3. Alloying Elements and Spheroidization:

- Certain alloying elements, such as magnesium (Mg) or cerium (Ce), are commonly added to cast iron to facilitate spheroidization.

- These elements react with carbon present in the cast iron, changing the morphology of graphite from flakes to nodules.

- The alloying elements act as nucleating agents, promoting the formation of spherical graphite during solidification.

4. Impact on Microstructure:

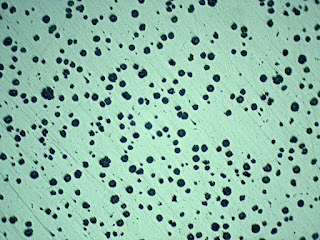

- Spheroidization profoundly affects the microstructure of cast iron, converting the flake graphite into nodular graphite.

- Nodular graphite consists of spherical or nearly spherical graphite nodules uniformly distributed within the metallic matrix.

- The presence of nodular graphite imparts unique mechanical properties to spheroidized cast iron.

5. Mechanical Properties of Spheroidized Cast Iron:

- Increased Ductility: The spheroidal graphite structure improves the ductility of cast iron, allowing it to withstand greater deformations before fracture.

- Enhanced Toughness: The presence of graphite nodules acts as crack arresters, hindering crack propagation and improving the material's resistance to fracture.

- Improved Machinability: Spheroidized cast iron exhibits improved machinability due to reduced hardness and the absence of sharp graphite flakes.

6. Applications:

- Spheroidized cast iron finds wide applications in various industries, including automotive, machinery, and construction.

- Its superior mechanical properties make it suitable for components that require high strength, ductility, and wear resistance.

- Common applications include engine blocks, cylinder heads, gears, and other structural parts subjected to heavy loads and thermal stresses.

7. Advantages and Limitations:

- Advantages:

- Increased ductility and toughness compared to flake graphite cast iron.

- Improved machinability, resulting in enhanced productivity and reduced tool wear.

- Greater resistance to cracking and fracture under high-stress conditions.

- Limitations:

- Spheroidization requires the addition of specific alloying elements or modification of the casting process, which may increase production costs.

- The process must be carefully controlled to ensure consistent and reliable results.

8. Factors Affecting Spheroidization in Cast Iron:

- Alloying Elements: The selection and concentration of alloying elements, such as magnesium or cerium, significantly influence the spheroidization process.

- Cooling Rate: The cooling rate during solidification affects the formation and distribution of graphite nodules, requiring careful consideration during casting.

- Heat Treatment: Proper heat treatment parameters, including temperature and time, play a crucial role in achieving optimal spheroidization in cast iron.

9. Different Spheroidization Techniques:

- Inoculation: The addition of inoculants containing specific alloying elements promotes the formation of graphite nodules during solidification.

- Magnesium Treatment: The introduction of magnesium into the melt induces spheroidization by reacting with carbon, transforming the graphite into nodules.

- Ladle Treatment: Spheroidization can also be accomplished by treating the molten cast iron in the ladle before casting, allowing for controlled addition of alloying elements.

10. Characterization of Spheroidized Cast Iron Microstructure:

- Metallography: Microscopic examination through metallographic techniques provides insights into the morphology, distribution, and size of graphite nodules.

- Image Analysis: Advanced image analysis tools enable quantitative assessment of nodularity, nodule count, and other microstructural parameters.

- Mechanical Testing: Various mechanical tests, such as tensile, hardness, and impact tests, assess the mechanical properties and performance of spheroidized cast iron.

11. Advancements and Innovations:

- Continuous Casting: Continuous casting processes offer improved control over cooling rates and solidification, facilitating the production of spheroidal graphite cast iron with desired microstructures.

- Alloy Design: Ongoing research focuses on developing new alloy compositions and optimizing existing ones to enhance spheroidization efficiency and achieve superior mechanical properties.

- Process Optimization: Efforts are being made to refine heat treatment parameters, inoculation techniques, and casting practices to achieve more consistent and reliable spheroidization results.

12. Industrial Significance and Benefits:

- Spheroidized cast iron exhibits a unique combination of strength, ductility, and wear resistance, making it suitable for demanding applications.

- Improved machinability reduces production costs and increases productivity.

- The enhanced thermal conductivity of spheroidized cast iron contributes to better heat dissipation and thermal management in various applications.

Microstructure preparation for SG iron involves several steps to reveal the graphite nodules and the surrounding matrix. Here is a detailed process for preparing the microstructure of SG iron:

1. Sample Preparation:

- Obtain a representative sample of the SG iron casting or component.

- Ensure that the sample is clean and free from any contaminants or surface irregularities that may affect the microstructural analysis.

2. Mounting:

- Embed the sample in a mounting material, such as a thermosetting resin or cold-mounting epoxy.

- The mounting material should securely hold the sample and provide stability during subsequent grinding and polishing steps.

3. Grinding:

- Begin the grinding process using a series of successively finer abrasive papers or grinding wheels.

- Start with a coarse-grit paper, such as 80 or 120 grit, to remove any surface irregularities or rough areas.

- Progressively move to finer grits, such as 240, 320, 400, and 600, to achieve a smooth and flat surface.

4. Polishing:

- After grinding, proceed to the polishing stage to further refine the surface and remove any scratches or marks left by the grinding process.

- Use a series of polishing cloths or pads, typically with diamond or alumina abrasive suspensions of decreasing particle size.

- The polishing process usually involves several steps, starting from a coarse abrasive suspension and gradually moving to finer suspensions.

- Rinse the sample with water between each polishing step to remove any residue.

5. Etching:

- Etching is a crucial step to selectively attack the metallic matrix and reveal the graphite nodules in the microstructure.

- Prepare an appropriate etchant for SG iron, which typically consists of a mixture of acids, such as nital or picral.

- The etchant composition and etching time may vary depending on the specific requirements and the desired contrast between the graphite and matrix.

- Dip the polished sample into the etchant for a specific duration, usually a few seconds to a few minutes, depending on the etchant and sample thickness.

- Carefully monitor the sample during etching to ensure the desired microstructural features are clearly visible.

6. Washing and Drying:

- After etching, thoroughly rinse the sample with water to remove any residual etchant and stop the etching process.

- Pat dry the sample using compressed air or a soft cloth to prevent watermarks or contamination.

7. Mounting and Cover Slipping (Optional):

- If required, the prepared sample can be mounted on a microscope slide using a mounting medium, such as a transparent resin or mounting adhesive.

- Place a cover slip over the sample to protect it and provide a clear view during microscopy.

8. Microscopic Examination:

- Place the prepared sample on a microscope stage and observe the microstructure using a metallurgical microscope.

- Use various magnifications to examine the graphite nodules, matrix, and any other microstructural features of interest.

- Capture images or document the microstructure using a digital camera or microscopy software for further analysis and reporting.

By following these steps, the microstructure of SG iron can be properly prepared for microscopic examination, allowing for a detailed analysis of the graphite nodules and the surrounding matrix. It's important to note that the specific etchants, grinding, and polishing techniques may vary based on the specific requirements, standards, and equipment available in different laboratories or industries.

Conclusion:

Spheroidized cast iron microstructure offers remarkable mechanical properties, including increased ductility, enhanced toughness, and improved machinability. This post aimed to provide a comprehensive explanation of spheroidization in cast iron, its impact on microstructure, and the resulting benefits. As a metallurgist, it's inspiring to witness the advancements and applications of spheroidized cast iron, contributing to the development of high-performance materials in diverse industries.

Remember to share your thoughts and experiences with spheroidized cast iron microstructure in the comments section. Let's keep the discussion going and continue exploring the fascinating world of metallurgy together!

No comments:

Post a Comment